Commercial & Institutional

Airtightness Testing in Large Buildings

Airtightness testing has long—since the 1980’s—been used to test high-performance housing. The 2012 version of the International Residential Code requires testing of every new home. Recently there has been a growing trend of testing the airtightness of large buildings as well. This session reviews why one would invest in airtightness testing for a large building, how the testing is done, how the results are interpreted, and how this information can be used.

Passiv for the Masses

Climate change has made mainstream adoption of high-performance buildings a priority, and the Passivhaus standard provides a means to assess and drive the performance of these buildings. With 16 certified Passivhaus buildings between them, industry leaders Adam Cohen, Alan Gibson and Mathew Omalia will discuss their experiences designing and constructing a wide spectrum of building types, styles and scales that meet the Passivhaus standard. Adam Cohen will discuss techniques used to design, manufacture and construct Passivhaus buildings that cost the same or less than comparable code buildings. Alan Gibson will talk about simplifying construction systems and assemblies, and lessons learned about structure, moisture, air sealing, and air quality. Matt Omalia will explore how to integrate Passivhaus parameters into the design process to create a new canon of architectural design. The presenters will use case studies including: single and multi-family homes, schools, university residence halls, and community buildings.

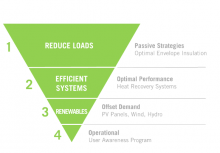

The Challenges of Net Zero Energy When It's Bigger than a Breadbox

Municipalities and other owners of large buildings are increasingly setting their sites on net-zero. This session will feature a case study of the 190,000sf Martin Luther King, Jr. School, the first of the Cambridge public schools to target NZE. Presenters will discuss the process, content and tools used at design workshops and user group meetings to gather, analyze, ideate and integrate information into design solutions while also facilitating cultural and behavioral change among users. They will highlight the challenges and gritty details involved in shepherding both this project and others—including issues related to codes, day-lighting, systems selection, load management, maintenance, and product selection. Attendees will learn what worked, what didn’t, and why.

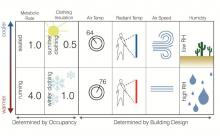

Room-side Low-e Coating: As Good as It Sounds?

The selection of a glazing type for a project is based on factors like thermal performance, impact on occupant thermal comfort and cost. Double pane glazing units with a room-side low-e coating are becoming popular, because their thermal properties and visual appearance are comparable to those of a triple pane unit, but at a lower cost. However, the impact of selecting one over the other can have significant impact on seasonal thermal comfort conditions, and the wrong choice could lead to a need for perimeter heating as a remedial measure. This session addresses the benefits and drawbacks of using double pane glass with a room-side low emissivity coating as a substitute to a more expensive and heavier triple pane unit. In order to ensure no perimeter heating is necessary with either unit, we introduce a method to quantify two factors affecting occupant thermal comfort: radiant temperatures and risk of downdraft.

Aiming at Zero: The Struggle to Get There

Everyone is talking about getting to zero energy by 2030. It’s easy to say, but very hard to do. What is the process and how do we ratchet down our EUI on each project? How can goal setting and Client priorities influence energy use and building performance? Can we actually get to zero? This lively moderated panel discussion will include the Architect, Engineer, and Owner/ Client on Weygand Hall at Bridgewater State University (completed in 2013) and on Keene State College (currently under construction). We will address the planning, design, and results of both projects as well as the ZNEB pilot study completed simultaneously with Weygand Hall. We will show best practices and lessons learned from each experience. We will focus on the continuum of these projects over time, how each process and learning experience influenced the next, and how this iterative approach leads to better energy performance and keeps us on track for 2030.

The True Performance of Your Hidden HVAC Equipment

How well does central ventilation equipment actually perform? VEIC and CLEAResult have respectively conducted field monitoring of Roof Top Units in commercial/institutional buildings and central Energy Recovery Ventilators in multifamily buildings. The outcomes? Although in certain cases not as bad as one would predict, this equipment is often underperforming, neglected, misunderstood, and installed and/or operated incorrectly. Come and learn more about our findings, how to improve current performance, and alternative design ideas to do it differently next time.

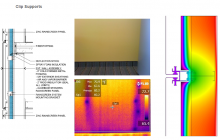

Break It or Lose It: Thermal Bridging in Building Envelopes

While thermal bridging is widely acknowledged to exist in modern commercial building envelopes, little is known on the significance of its impact. Utilizing infrared images taken from targeted assemblies at 15 recently completed buildings; we have seen a range up to 70% less than the design intended R-value. This range shows the unintended impact that design details can have on thermal performance.

We identified 16 common areas of thermal bridging that were frequently observed in the buildings surveyed. Broken into two broad categories of façade systems and transitions / penetrations, they range from curtain wall systems, to existing wall renovations, to conditions such as parapets and transitions to foundation.

The outcome of this research is a better understanding of thermal performance of commercial façades in order to help architects and building professionals understand the real impact of common thermal bridges and present alternatives to the industry standards that enhance performance.

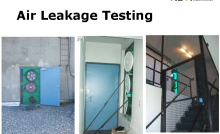

Air Leakage: What You See is Not What You Get

Air leakage is an important consideration in all construction. Tighter buildings are more energy efficient and comfortable. Although large buildings are rarely blower door tested, architects, enclosure consultants, manufacturers, and installers spend time and money to provide air tight buildings. Details within the contract documents and subsequent shop drawings indicate the intended location of the air barrier. However, over the course of mockup construction, mockup testing, and project construction, air leakage issues often arise that were not addressed prior, generally at unusual conditions and transitions. These locations can be difficult to detail and are typically overlooked. This presentation will first review the basics of air leakage detailing, and then provide specific examples where project documentation did not address air leakage sites, which were found in the field. Implemented field fixes will also be presented. Although project-specific, these case studies will demonstrate typical locations that must be carefully vetted during detailing.

Innovation Drives Operations

Discussion of demand management, battery, elevator technologies - all new ways to manage energy usage in buildings that result in real savings to the owner/tenants.

Making Money by Saving Energy

Do all major capital improvements result in better buildings with lower operating costs, better energy management strategies and improved data collection? This panel will discuss the changes made throughout their portfolios to improve NOI, reduce maintenance costs and improve operations, and present the challenges associated with planning for new technologies and staff training so savings can be realized.